assalaamu'alaikum :)

above is the photo of my aquarium after LED strip lighting installed. nice :?

Here are the steps I did:

- bought "LED 5730 Strip with built in aluminium heatsink strip" from tokopedia.com. it is only priced IDR 30,000/meter (contains 72 LEDs).

according to the seller, it was 36 Watts LED. however it is impossible LED is setup in its' max power limit. Otherwise it is already dead :).

2. cut the LED strip into 2 halves using cutting pliers, then glue onto PVC rectangle conduit (IDR 3,500) using Silicone glue (IDR 5,000). note: aluminium bar (15,000 / 6 meters) is better since aluminium can help dissipating heat and as well as very strong metal frame for the LED.

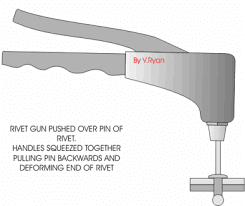

3. Join the PVC/aluminium frame using superglue or rivet nail.

4. bought second hand AC-DC Adaptor (IDR 25,000: 24 volts 2 Amperes, because I solder the LED in series 12Volts x 2)

5. OK, then try it up on my floor: quite bright!

6. Set it on my aquarium.... awesome

at night, it induce photosynthesis too:

Photosynthesis video: you can see the Oxygen bubbles were coming out from the leaves!!!